Stainshield TIG gas has been developed to have improved characteristics over argon suited to manual applications, including TIG welding austenitic stainless steel (300 series). Welders find the more fluid weld pool easier to control giving flatter, smoother weld beads.

View our video on Stainshield TIG:

Primarily used for plasma welding of austenitic stainless steels. The thicker the section of material to be welded, the higher the hydrogen content in the plasma shielding gas.

- Easier and faster to use than argon, the small amount of hydrogen helps to scavenge any oxygen from around the weld area, producing a bright clean weld and smooth surface finish.

- The hydrogen content of the shielding gas stiffens the welding arc and increases the fluidity of the weld pool, making it easier to produce a neat, tidy weld bead.

- Improved fluidity increases welding speed compared to argon, resulting in lower weld costs.

Key Features

- Gas Composition: 98.5% Ar, 1.5% H2

- Gas Type: Welding gas

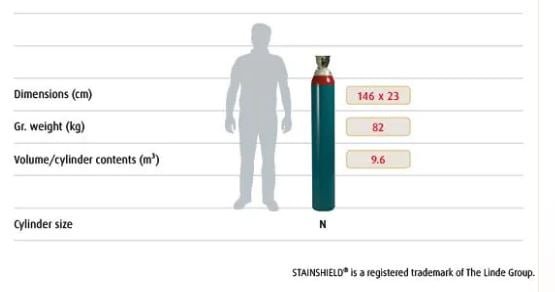

- Supply Mode: Cylinders

- Welding Type: Shielding

- Outlet connection: 5/8” BSP female right hand cone recessed

- Welding Processes: Arc welding processes

- ISO Classification: ISO 14175-R1-ArH-1.5

- Cutting & Lasing Gas: Plasma cutting gas

- TIG Welding Gas: Stainshield range (stainless steel)