The BOC Argoshield range #

An advanced range of shielding gases delivering superior welding performance, productivity and lowering customer operating costs. Developed primarily for the MIG welding of steel, Argoshield gases deliver improved welding performance.

The gases are simple to use, achieve fast travel speeds resulting in minimal distortion, spatter and provide consistently good penetration and fusion with flat weld profiles. These excellent ‘first time’ results help to cut the frequency rework and post-weld treatment – a key factor in driving costs down for BOC customers.

Argoshield Light #

Argoshield Light is specifically formulated for MIG welding sheet and thin sections of mild steel less than 4mm thick. The low levels of carbon dioxide and oxygen in the weld reduce the risk of burning through and leaving holes in the weld area. The addition of oxygen improves the flow of the molten weld metal producing flatter welds with lower levels of reinforcement. This can greatly reduce the need to machine or grind down the reinforcement, which is a known stress raiser, reducing production costs.

Argoshield Light has excellent arc stability minimising the amount of spatter produced. Reduced spatter means less welding wire being wasted, as well as shorter clean up time. This makes the product ideal for welding components that are painted or powder coated after welding. The faster welding speeds achievable with this gas coupled with a low heat input also help to reduce welding distortion.

- Combines 2% Oxygen, 5% Carbon Dioxide, balance Argon

- Formulated for MIG welding sheet and thin sections of mild steel less than 4mm thick

- Ideal for duct and sheet-metal engineering industries

- A suitable gas in automotive component manufacturing and vehicle repair as it provides dip transfer in all positions with solid wire

- The oxidising potential of this mixture has a tendency to produce welds with a black surface film. In many stainless steel applications, this type of surface finish would be considered unacceptable and removal of the surface film would be required. Cleaning away this residue can be both time-consuming and costly. Due to this, other products such as the BOC Stainshield range of gases would be recommended.

View our video on Argoshield Light:

- Increases productivity with high travel speeds, minimal distortion and spatter

- Consistently good penetration and fusion, flat weld profiles

- Can also be used for MIG welding standard-grade stainless steel in less critical applications

- Less rework and post-weld treatment, saving operator time and money

- Formulated to deliver optimum results on mild steel under 4mm in thickness

Key Features

- Gas Composition: 93% Ar, 5% CO2, 2% O2

- Gas Type: Welding gas

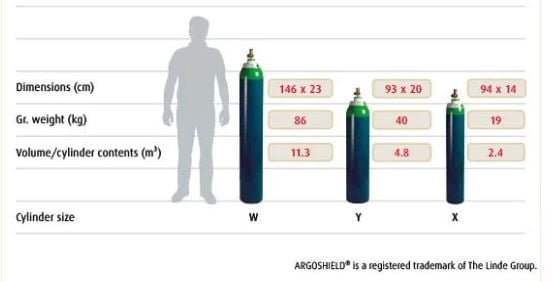

- Supply Mode: Cylinders

- Welding Type: Shielding

- Qualities: Good penetration, fusion with minimal distortion and spatter.

- Efficiency: Removes need for rework with excellent first-time results

- Outlet connection: 5/8” BSP female right hand cone recessed at 230 bar

- Welding Processes: Arc welding processes

- ISO Classification: ISO 14175-M14-ArCO-5/2

- MIG/MAG welding gas: Argoshield range (carbon steel)