Acetylene (also known as dissolved acetylene), is the hottest and most efficient of all the fuel gases, BOC Acetylene gas cylinders offers customers, low ignition energy, a localised flame and reducing wasted heat.

When acetylene is used in cutting processes, an improved cut quality, higher cutting speed, and faster cut initiation time is achieved.

These advantages can greatly improve productivity.

Acetylene is a highly-versatile fuel gas making it the gas of choice for processes including cutting, gas welding, flame heating, flame gouging, flame straightening and brazing.

Customers buying acetylene from BOC receive industry-leading standards of safety.

Our fuel gases are fitted with a left-hand cylinder valve to provide additional safety benefits.

Acetylene is provided in a specially designed gas cylinder to prevent decomposition and ensure maximum longevity.

- The only fuel gas hot enough to weld steel.

- Mainly used for gas welding, cutting, flame heating, flame gouging, flame straightening and flame cleaning

- More efficient – save time and money by switching to acetylene

- Improved cut quality – high cutting speed and fast cut initiation time due to its unique properties

- Slightly lighter than air and will collect at ceiling level

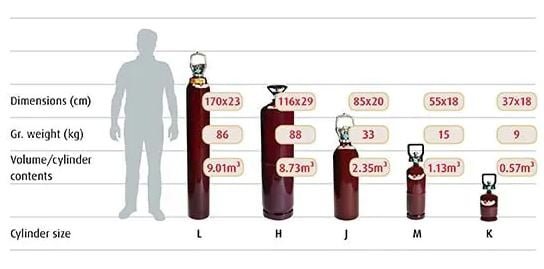

- Supplied in multiple cylinder sizes (0.57m3 to 9.01m3 capacity)

Key Features

- Gas Type: Fuel gas

- Supply Mode: Cylinders

- Gas Composition: C2H2 – Acetylene

- Cylinder Capacity Options: 0.57m3 to 9.01m3

- Qualities: High cutting speed and versatile

- Efficiency: Saves time and money

- Cutting & Lasing Gas: Oxy-fuel gas