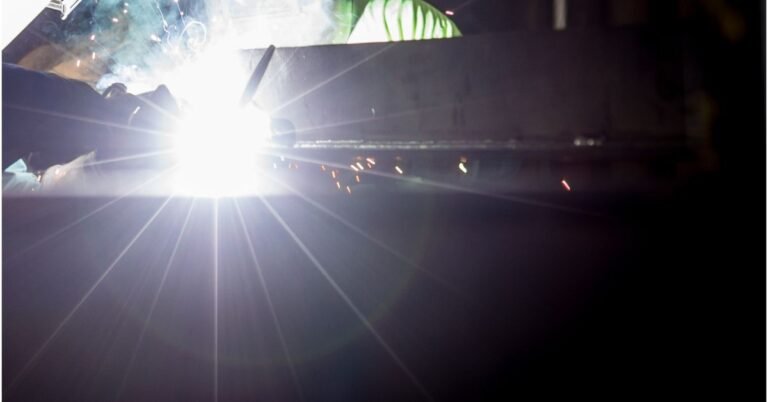

Unveiling the Role of Argon Gas in Welding

Argon gas, often referred to as the “invisible helper” in the world of welding, plays a crucial role in creating strong and high-quality welds. From TIG to MIG welding, argon gas serves as a shielding agent that ensures weld integrity and minimizes defects. In this blog post, we’ll delve into the significance of argon gas in welding, its unique properties, applications, and safety considerations.

What is Argon Gas?

Argon is a noble gas that constitutes about 0.93% of the Earth’s atmosphere. It is colorless, odorless, and tasteless, making it an ideal candidate for various industrial applications, including welding.

Why Do You Need Shielding Gas for Welding?

Shielding gas is essential in welding as it creates a protective environment around the weld pool. This shield prevents the molten metal from coming into contact with atmospheric gases like oxygen, nitrogen, and hydrogen, which can lead to defects such as porosity, brittleness, and oxidation.

What Makes Argon a Good Welding Gas?

Argon possesses several properties that make it an excellent choice for welding:

- Inert Nature: Argon is chemically inert and does not react with metals at high temperatures, ensuring a clean and defect-free weld.

- High Density: The density of argon gas creates a stable and effective shield around the weld pool, preventing contamination.

- Thermal Conductivity: Argon’s high thermal conductivity aids in dispersing heat, contributing to controlled and precise welding.

Pure Argon for TIG Welding:

TIG (Tungsten Inert Gas) welding relies on a continuous supply of pure argon gas. This is particularly suitable for non-ferrous metals like aluminum, stainless steel, and copper, where the absence of reactive gases is essential to maintain weld quality.

Argon/CO2 Mix for MIG Welding:

In MIG (Metal Inert Gas) welding, a mixture of argon and carbon dioxide (CO2) is commonly used. This combination balances the need for shielding and deeper penetration, making it suitable for mild steel and some stainless steel applications.

Argon and Other Gas Mixes:

Argon is often blended with other gases, such as helium and oxygen, to enhance specific welding characteristics. These mixtures are tailored to different materials and welding processes.

Dangers of Argon:

While argon itself is not toxic, it displaces oxygen in the air. In confined spaces or areas with poor ventilation, an excess of argon gas can lead to oxygen deficiency and potentially be harmful. Proper ventilation and safety measures are essential when working with argon gas.

Rent Free Argon Gas for Welding at Sultani Gas:

For welders seeking a reliable source of argon gas, Sultani Gas provides rent-free argon gas cylinders. Ensuring a steady supply of high-quality argon gas, Sultani Gas supports welders in their pursuit of exceptional welds.

Conclusion:

Argon gas is an unsung hero in the welding world, enabling welders to create strong, flawless, and durable joints. From its role as a shielding gas in TIG and MIG welding to its unique properties, argon gas elevates the quality and integrity of welds across various applications. As you embark on your welding journey, understanding the significance of argon gas and its safe usage will empower you to master the craft and achieve outstanding results.